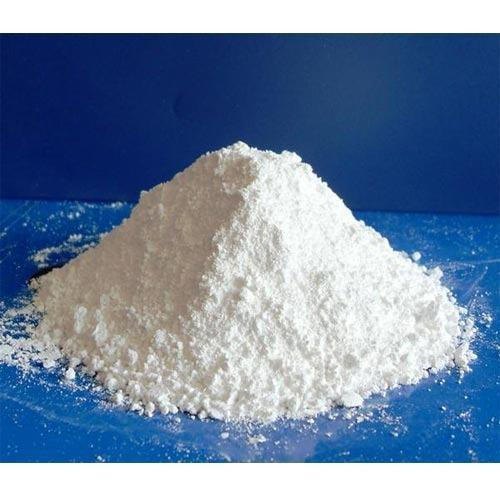

Micronized Barium Sulfate (X-ray applications)

We are the stalwarts in the domain of manufacturing, supplying, wholesaling, and exporting Micronized Barium Sulfate (X-ray applications) These flavor grade chemicals are processed using pure and accurate ingredients that are procured from reliable and trusted vendors of the market. Our range is available in the market at leading prices in packs of different quantities.

Micronized Barium Sulfate is commonly used in the plastering and construction of X-ray rooms for its unique properties that make it suitable for radiation shielding.

Here are some ways in which micronized barium sulfate is employed in this context:

Radiation Shielding:

Density: Micronized barium sulfate is a high-density material. This property is crucial for effective radiation shielding. Placing a dense material like barium sulfate in the walls helps absorb and attenuate the X-ray radiation, preventing it from penetrating through the walls.

Thickness Reduction: By adding micronized barium sulfate to the plaster or construction material, the thickness required for effective radiation shielding can be reduced. This is important in maintaining a balance between structural integrity and efficient radiation protection.

Customization of Plaster and Construction Materials:

Additive in Plaster: Micronized barium sulfate can be added as an additive to plaster or concrete mixtures used in construction. This allows for the creation of custom formulations with specific radiation shielding properties.

Paints and Coatings: Barium sulfate can also be used as an additive in paints and coatings applied to walls and surfaces. This provides an additional layer of radiation protection.

Compatibility with Other Materials:

Integration with Construction Materials: Micronized barium sulfate can be easily integrated into various construction materials, ensuring compatibility with existing building practices.

Stability: The inclusion of barium sulfate does not compromise the stability or durability of the construction material, allowing for the creation of robust structures.

Regulatory Compliance:

Standard Compliance: The use of micronized barium sulfate in the construction of X-ray rooms is often in compliance with regulatory standards and guidelines for radiation protection in healthcare facilities. It helps meet the requirements for the safe operation of X-ray equipment.

Cost-Effective Solution:

Efficient Shielding: The high density of micronized barium sulfate allows for efficient shielding, potentially reducing the overall cost of constructing X-ray rooms compared to alternative materials that might require greater thickness for the same level of protection.

Calculate Dosage Percentage:

Typically, the dosage of micronized barium sulfate is expressed as a percentage of the total weight of the plaster or construction material. The exact percentage will vary based on the material composition, thickness requirements, and radiation attenuation properties of the barium sulfate.

It’s important to note that the use of micronized barium sulfate in construction, especially in sensitive environments like X-ray rooms, should be carried out by professionals who are knowledgeable about radiation shielding requirements and local building codes. Additionally, regular inspections and maintenance are essential to ensure the continued effectiveness of the shielding.