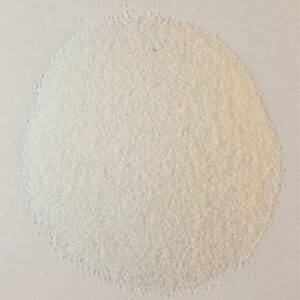

White Aluminum Oxide Grit (Grade – 30 M)

We are the stalwarts in the domain of manufacturing, supplying, wholesaling, and exporting White Aluminum Oxide Grit (Grade – 30 M) These flavor grade chemicals are processed using pure and accurate ingredients that are procured from reliable and trusted vendors of the market. Our range is available in the market at leading prices in packs of different quantities.

White Aluminum Oxide Grit (Grade – 30 M) is a versatile abrasive material commonly used in sandblasting and various other industries for surface preparation, cleaning, and finishing applications. Its properties make it suitable for a wide range of uses, including:

Sandblasting and Surface Preparation: White aluminum oxide grit is often used for sandblasting surfaces to remove rust, paint, coatings, and contaminants from various materials such as metal, wood, glass, and ceramics. It provides a clean and consistent surface finish.

Deburring: It is used to remove sharp edges and burrs from metal parts, ensuring they are safe to handle and fit properly in assemblies.

Cleaning and Polishing: This abrasive is used for cleaning and polishing applications in industries like automotive, aerospace, and jewelry making. It can effectively remove stains, oxidation, and corrosion from metal surfaces.

Lapping and Honing: White aluminum oxide grit is utilized in precision machining applications such as lapping and honing to achieve a high degree of surface smoothness and flatness in products like optical lenses, semiconductor wafers, and precision bearings.

Grinding and Sharpening: It can be used as a grinding media for precision grinding operations, including tool sharpening and blade grinding, where a high-quality finish is required.

Thermal Spray Coatings: In the thermal spray process, white aluminum oxide grit can be used as a feedstock material for creating coatings on various substrates to improve wear resistance, corrosion resistance, and other properties.

Cutting and Shaping: It is employed in abrasive cutting and shaping processes, such as waterjet cutting and abrasive wheel cutting, to shape materials like metal, stone, and glass.

Refractory and Ceramic Industries: White aluminum oxide is used as a raw material in the production of refractories, ceramics, and abrasives. It contributes to the heat resistance and durability of these products.

Aerospace and Aircraft Maintenance: It is used for aircraft maintenance to remove old coatings, corrosion, and other imperfections from aircraft surfaces, ensuring safety and performance.

Electronics Manufacturing: In the electronics industry, white aluminum oxide grit is used for cutting and shaping semiconductor materials and components with precision.

Medical Device Manufacturing: It can be used for polishing and finishing medical devices to ensure their smoothness and cleanliness.

Mold and Die Casting: White aluminum oxide is employed for cleaning and finishing molds and dies in manufacturing processes.

Jewelry and Artwork: Artisans and jewelers use white aluminum oxide for polishing and finishing metal, gemstones, and glass in jewelry and art creations.

Stone and Concrete Cutting and Polishing: It is used in the stone and concrete industry for cutting, shaping, and polishing natural and engineered stone surfaces.

Woodworking: In woodworking, it can be used for sanding and finishing wood surfaces to achieve a smooth and polished look.

White aluminum oxide grit is valued for its hardness, durability, and ability to produce a consistent finish. It is also preferred in applications where minimal contamination or color transfer is critical, such as in the aerospace and medical industries. However, safety precautions, including the use of personal protective equipment, are essential when handling this abrasive material due to its potential health hazards when inhaled.

White Aluminum Oxide Grit has several important applications in the steel industry due to its abrasive and cleaning properties. Here’s a more detailed look at how it is used in this sector:

Surface Preparation: In the steel industry, one of the primary applications of white aluminum oxide grit is surface preparation. Steel surfaces need to be cleaned and prepared before various processes such as welding, painting, or galvanizing. White aluminum oxide is used in sandblasting to remove rust, mill scale, and other contaminants from the surface, ensuring proper adhesion and coating quality.

Cleaning and Descaling: Steel manufacturing processes can leave behind scale, oxides, and other impurities on the surface of steel products. White aluminum oxide grit is employed to clean and descale steel parts, improving their appearance and ensuring they meet quality standards.

Shot Peening: Shot peening is a process used to strengthen steel components by inducing compressive stresses in their surfaces. White aluminum oxide grit can be used as the peening media to create controlled surface compression, increasing the fatigue life and durability of steel parts, such as automotive springs and gears.

Deburring and Edge Rounding: After cutting or machining steel parts, sharp edges and burrs can be left behind. White aluminum oxide grit is used to deburr and round the edges of steel components, making them safer to handle and assemble.

Blending and Grinding: In steel fabrication and manufacturing, white aluminum oxide grit is used in grinding operations to achieve specific surface finishes or dimensional tolerances on steel components. It helps in shaping and refining steel surfaces to meet desired specifications.

Maintenance and Repair: In the steel industry, maintenance and repair tasks are common. White aluminum oxide grit is used for cleaning and preparing surfaces before welding or repairing steel structures, ensuring the integrity and longevity of the repairs.

Surface Finishing: For some steel products, a smooth and aesthetically pleasing surface finish is required. White aluminum oxide grit can be used in abrasive polishing processes to achieve the desired surface quality.

Heat Treatment: During heat treatment processes, steel parts may develop undesirable surface layers or scales. White aluminum oxide grit can be used to remove these surface imperfections, ensuring that the steel meets the required specifications after heat treatment.

Blast Cleaning: In steel manufacturing facilities, blast cleaning with white aluminum oxide grit is an effective method to remove dirt, scale, and contaminants from steel products before further processing or shipping.

Removal of Corrosion: When steel components are exposed to environmental conditions, they may develop corrosion. White aluminum oxide grit can be used to remove corrosion from steel surfaces, restoring their integrity and appearance.

Overall, white aluminum oxide grit plays a crucial role in maintaining the quality and performance of steel products in various stages of production and during their service life. It contributes to the durability, safety, and appearance of steel components used in construction, automotive, aerospace, and many other industries.