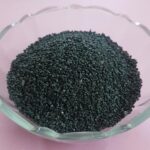

Fumed Silica (EROSIL – NV/200)

We are the stalwarts in the domain of manufacturing, supplying, wholesaling, and exporting Fumed Silica (EROSIL – NV/200). These flavor grade chemicals are processed using pure and accurate ingredients that are procured from reliable and trusted vendors of the market. Our range is available in the market at leading prices in packs of different quantities.

Fumed Silica (EROSIL – NV/200) Fumed silica, such as Erosil-NV/200, is a type of amorphous, nano-sized silica produced by the vapor-phase hydrolysis of silicon compounds (also known as pyrogenic silica) is a versatile material that has several applications in various industries. In the automotive industry, fumed silica is commonly used as a reinforcing filler in the manufacture of brake pads, brake shoes, and brake linings.

Here are some of the applications and uses of Fumed Silica (EROSIL – NV/200) in the manufacture of brake pads, brake shoes, and brake linings:

1.Improved wear resistance: Fumed Silica (EROSIL – NV/200) helps to improve the wear resistance of brake pads, shoes, and linings. This is because it increases the strength and durability of the material, allowing it to withstand the friction and heat generated during braking.

2.Increased thermal stability: Fumed Silica (EROSIL – NV/200) also improves the thermal stability of brake pads, shoes, and linings. This is important because braking generates a lot of heat, and the material needs to be able to withstand it without degrading or losing its braking performance.

3.Better bonding: Fumed Silica (EROSIL – NV/200) can improve the bonding between the friction material and the metal backing plate of brake pads and shoes. This helps to prevent delamination and improves the overall performance of the brake system.

4.Noise reduction: Fumed Silica (EROSIL – NV/200) can also help to reduce the noise generated by the brake system. This is because it helps to dampen vibrations and reduce the frequency of noise generated by the brake pads or shoes.

Overall, fumed silica is a useful material in the manufacture of brake pads, shoes, and linings, as it improves their wear resistance, thermal stability, bonding, and noise reduction properties.