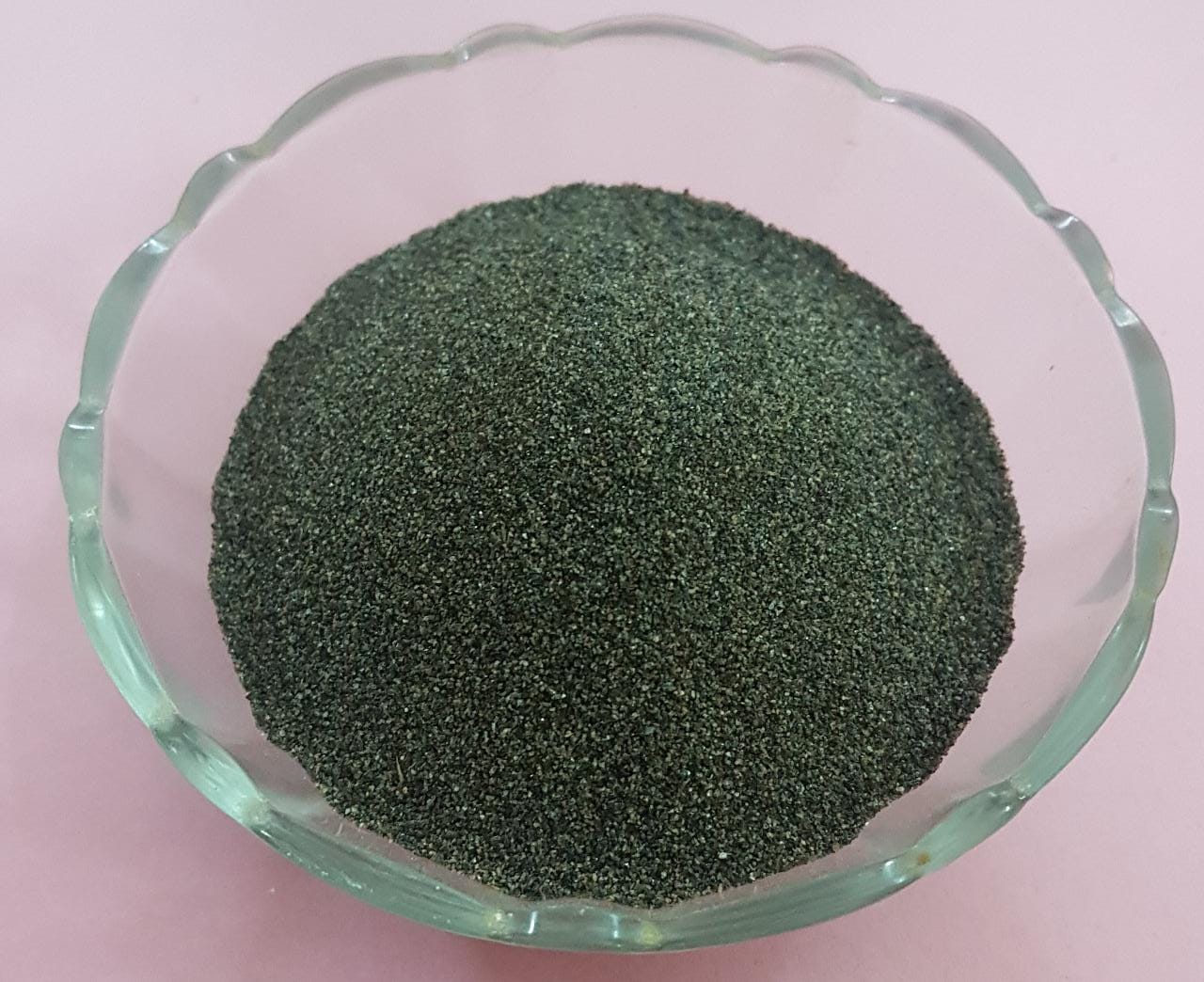

Brown Aluminum Oxide Grit 60

Brown Aluminum Oxide Grits, also known as brown fused alumina, are abrasive particles that are used in various industrial applications due to their hardness, toughness, and durability.

Here are some of the uses and benefits of brown aluminum oxide grits:

Uses:

Abrasive Blasting: Brown aluminum oxide grits are widely used as abrasive blasting media for surface preparation, cleaning, and roughening of various materials. They are particularly effective for removing rust, paint, scale, and other coatings from metal surfaces.

Grinding and Polishing: These grits are used as abrasive grains in grinding wheels, belts, and discs for metalworking, woodworking, and stone fabrication. They are used to shape and finish materials with precision.

Lapping and Polishing: Brown aluminum oxide grits are used in the manufacturing of precision optics, lenses, and semiconductor components through processes like lapping and polishing.

Refractory Materials: They are used in the production of refractory materials like bricks, crucibles, and ceramics due to their high melting point and resistance to thermal shock.

Anti-Skid Surfaces: Brown aluminum oxide grits can be added to paints, coatings, and epoxy resins to create anti-skid surfaces on floors, ramps, and other areas where slip resistance is important.

Sandpaper and Abrasive Cloth: These grits are utilized in the production of sandpaper and abrasive cloth for sanding and smoothing surfaces in woodworking, metalworking, and other applications.

Precision Casting: In precision casting, brown aluminum oxide grits can be used as a shell molding material to create molds for intricate metal castings.

Benefits:

Hardness and Durability: Brown aluminum oxide grits are known for their high hardness, which makes them effective for grinding, cutting, and polishing tough materials such as metals, ceramics, and composites.

Sharp Edges: These grits have sharp cutting edges that enable efficient material removal, resulting in improved productivity and reduced processing time.

brown aluminum oxide: Due to their toughness and resistance to wear, brown aluminum oxide grits have a longer lifespan compared to other abrasives, reducing the frequency of replacement.

Consistency: They provide consistent particle size distribution, ensuring uniform results and predictable outcomes in various applications.

Chemical Inertness: Brown aluminum oxide is chemically stable, which means it doesn’t react with most materials, making it suitable for a wide range of applications, including those involving sensitive materials.

Heat Resistance: These grits can withstand high temperatures, which is essential for applications involving metalworking, refractory materials, and other high-heat environments.

Versatility: Brown aluminum oxide grits are versatile and can be used for various applications across industries, making them a valuable material in manufacturing and production processes.

It’s important to note that while brown aluminum oxide grits offer numerous benefits, safety precautions should be taken when handling and using them, as they can generate fine particulate matter that may pose respiratory hazards. Proper protective equipment and ventilation should be employed to minimize health risks.